Efficient workflows for bespoke solutions

Lean production is a matter of course at SCHEUERMANN + HEILIG. In practice, this means using robust, highly efficient and flexible processes to make top-quality products. We create value without wasting anything. Our customers know that we consistently live up up to our motto of Performing Perfection while taking nothing for granted: we always strive to solve problems in the most suitable, direct way.

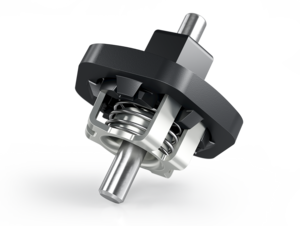

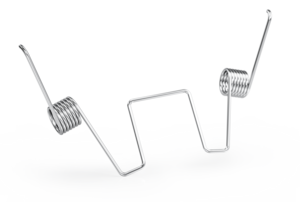

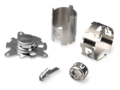

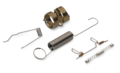

In close cooperation with the customer, our experienced technicians develop custom-tailored solutions, whether it’s for individual components, assemblies or system solutions. Then the required tools are individually designed, specially built and seamlessly integrated for making high-precision products. This permits cost-effective, speedy manufacture of everything from discrete parts across highly complex assembles and innovative hybrid components in outstanding quality.